Your Gas to liquids economics images are available. Gas to liquids economics are a topic that is being searched for and liked by netizens now. You can Download the Gas to liquids economics files here. Download all royalty-free vectors.

If you’re looking for gas to liquids economics images information connected with to the gas to liquids economics topic, you have visit the right site. Our website frequently provides you with suggestions for seeking the maximum quality video and picture content, please kindly hunt and locate more informative video content and images that fit your interests.

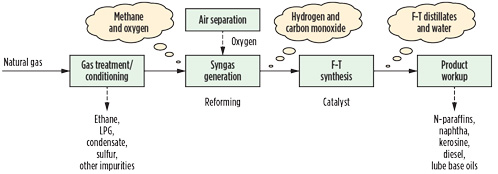

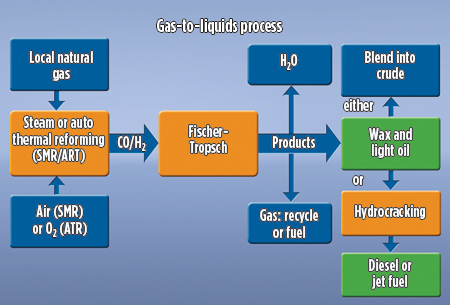

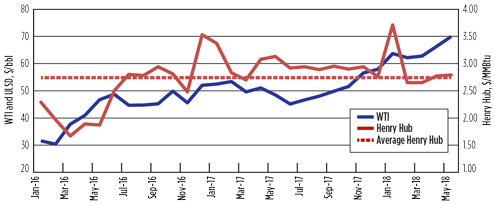

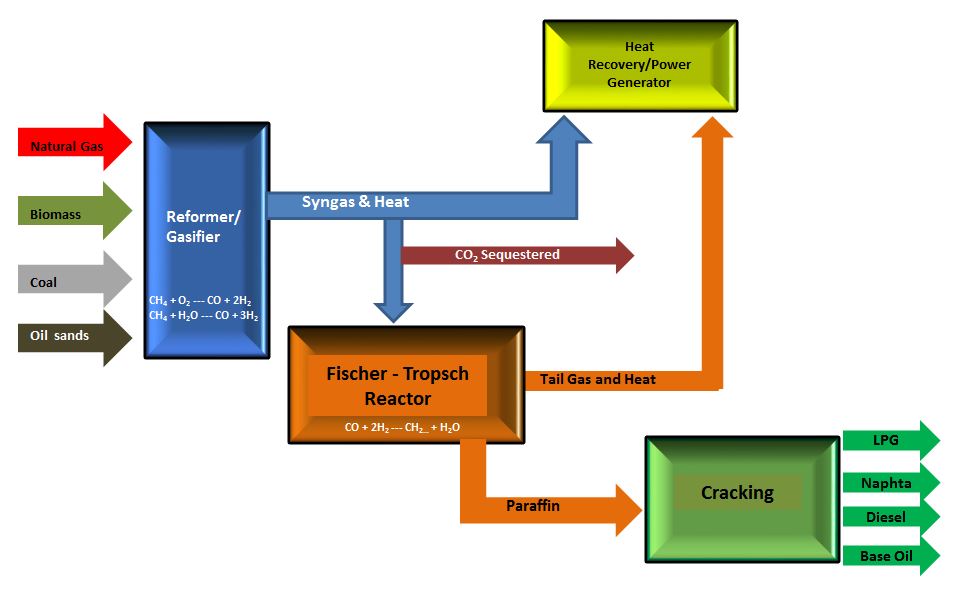

Gas To Liquids Economics. Gas-to-liquids technologies typically use the Fischer-Tropsch Process to convert natural gas to petroleum products. The case for gas-to-liquids Economic justification There is an economic incentive for gas-to-liquids conversion when there is a meaningful price difference between natural gas and crude oil. Gas-to-liquids GTL has emerged as a commercially-viable industry over the past thirty years offering market diversification to remote natural gas resource holders. 2004 152 406-481 p436.

Gas To Liquids Technology Offers Solution For Stranded Gas From aogr.com

Gas To Liquids Technology Offers Solution For Stranded Gas From aogr.com

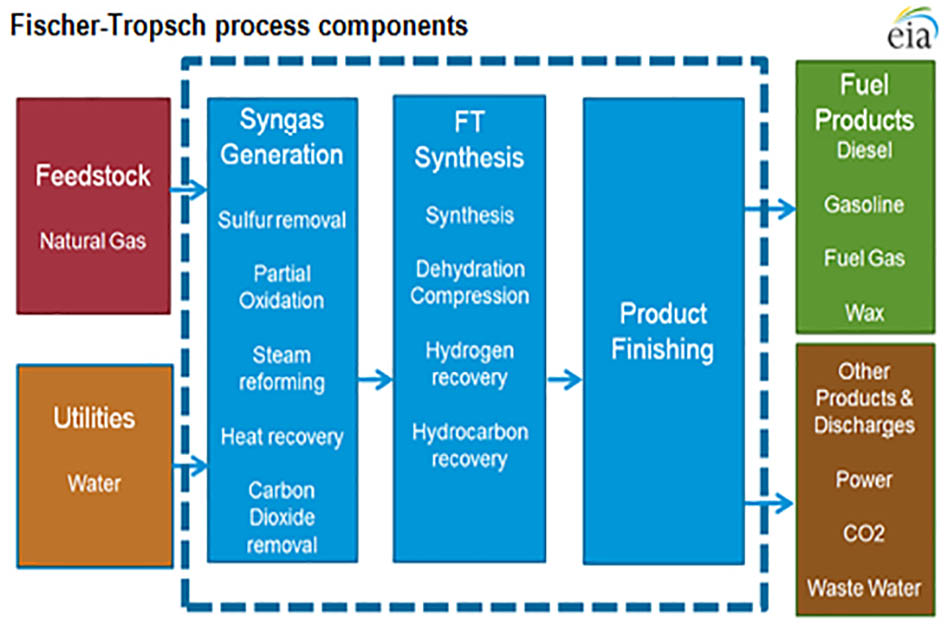

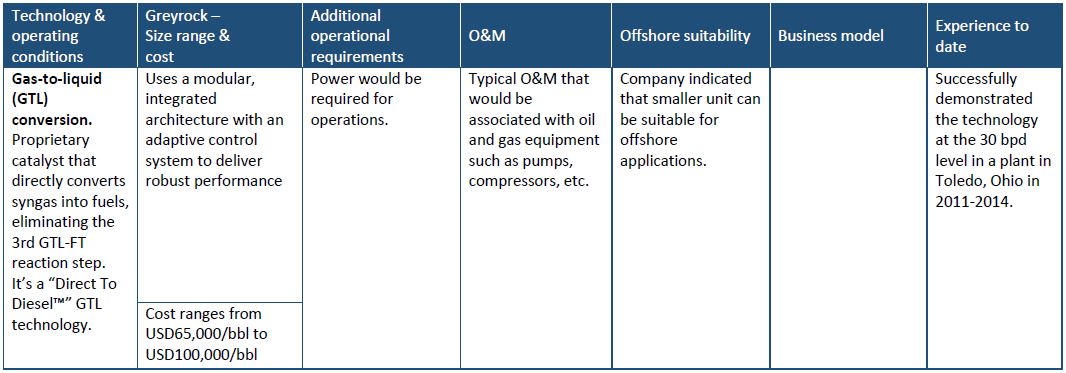

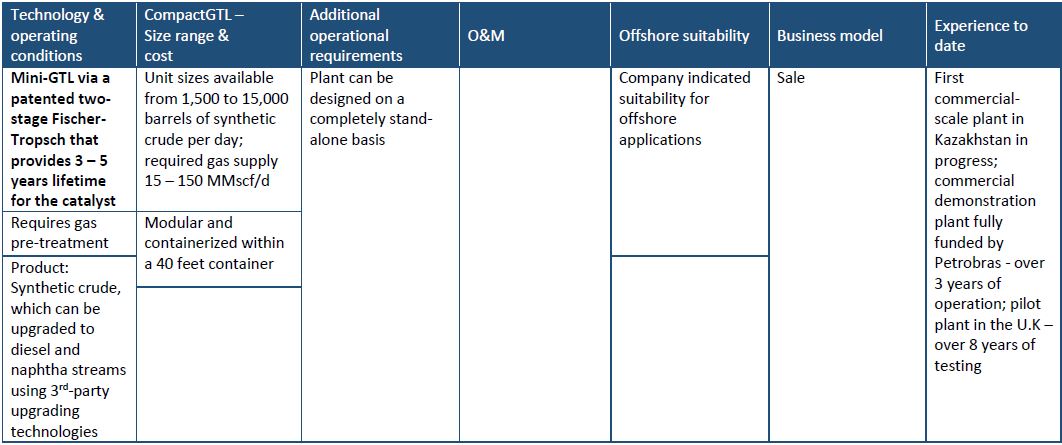

Modular small-scale gas-to-liquids plants can improve well economics by enabling producers to convert stranded or excess gas into high-value liquids. Gas-to-liquids GTL is a process that converts natural gas to liquid fuels such as gasoline jet fuel and diesel. The case for gas-to-liquids Economic justification There is an economic incentive for gas-to-liquids conversion when there is a meaningful price difference between natural gas and crude oil. Process Economics Program Report 247B SMALL SCALE GAS-TO-LIQUIDS TECHNOLOGY December 2011 Fischer-Tropsch synthesis generally involves the synthesis of alkane waxes of varying chain lengths and oxygenates from synthesis gas syngas which consists primarily of a mixture of carbon monoxide and hydrogen. Methane is the second highest contributor to the greenhouse effect. While manufacturing economics are reviewed the.

2004 152 406-481 p436.

Gas-to-liquids GTL has emerged as a commercially-viable industry over the past thirty years offering market diversification to remote natural gas resource holders. Natural gas to liquids technology appears to have reached the threshold of economic attractiveness when gas is priced at about 050 per Mscf. Process Economics Program Report 247B SMALL SCALE GAS-TO-LIQUIDS TECHNOLOGY December 2011 Fischer-Tropsch synthesis generally involves the synthesis of alkane waxes of varying chain lengths and oxygenates from synthesis gas syngas which consists primarily of a mixture of carbon monoxide and hydrogen. Natural Gas using GTL zNeed for economic utilization of associated gas zDesire to monetize significant reserves of non-associated and particularly stranded natural gas 80 of the 5000 TCF proven NG reserves are stranded zReduction in cost of transport of NG from producing to consuming regions same principle as with LNG zEnvironmental concerns. Modular small-scale gas-to-liquids plants can improve well economics by enabling producers to convert stranded or excess gas into high-value liquids. Click to enlargeEditors Note.

Source: nytimes.com

Source: nytimes.com

This paper examines the economics of Fischer-Tropsch gas to liquids manufacture using recent literature articles to develop process capital costs operating expenses liquid product value parameters and other economic factors to paint a general picture of the technologys current economic status. This is best illustrated with an example. Modular small-scale gas-to-liquids plants can improve well economics by enabling producers to convert stranded or excess gas into high-value liquids. Natural Gas using GTL zNeed for economic utilization of associated gas zDesire to monetize significant reserves of non-associated and particularly stranded natural gas 80 of the 5000 TCF proven NG reserves are stranded zReduction in cost of transport of NG from producing to consuming regions same principle as with LNG zEnvironmental concerns. Economics of global gas-to-liquids GtL fuels trading based on hybrid PV-Wind power plants Mahdi Fasihi Dmitrii Bogdanov and Christian Breyer Lappeenranta University of Technology Lappeenranta Finland E-mails.

Source: everycrsreport.com

Source: everycrsreport.com

2004 152 406-481 p436. For the assumed Base Case minimum returns on investment are judged to be likely when crude oil is priced between 1400 to 1600 per barrel and more attractive returns are judged to be likely when crude oil is priced at a. The most common technique used at GTL facilities is Fischer-Tropsch F-T synthesis. This is best illustrated with an example. Gas-to-liquids GTL has emerged as a commercially-viable industry over the past thirty years offering market diversification to remote natural gas resource holders.

Source: gasprocessingnews.com

Source: gasprocessingnews.com

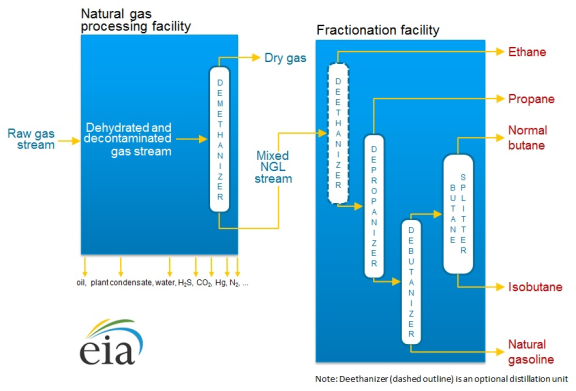

Natural Gas using GTL zNeed for economic utilization of associated gas zDesire to monetize significant reserves of non-associated and particularly stranded natural gas 80 of the 5000 TCF proven NG reserves are stranded zReduction in cost of transport of NG from producing to consuming regions same principle as with LNG zEnvironmental concerns. Economics of global gas-to-liquids GtL fuels trading based on hybrid PV-Wind power plants Mahdi Fasihi ymahdifasihilutfi 4 Motivation íFossil fuels increasing demand diminishing resources emissions íRE available but energy system transformation is challenging fluctuating RE and energy storage 100 electrification impossible for mobility sector. NGLs enter the processing plant as gas in the inlet stream and then are extracted and converted exiting the plant as liquids. Natural gas to liquid transportation fuels. 1 2005 The Economics of Gas to Liquids Compared to Liquefied Natural Gas by Michael J.

Source: mdpi.com

Source: mdpi.com

1 2005 The Economics of Gas to Liquids Compared to Liquefied Natural Gas by Michael J. Gas processing economics are all about converting hydrocarbons from one state gas to another liquids and understanding how much energy each gas and liquid component contains. Gas-to-liquid GtL technologies first convert natural gas into syngas then it into liquids such as methanol FischerTropsch fuels or dimethyl ether. The GTL process utilizes the Fischer Tropsch process to convert gas to liquid fuels a technology dating back to the 1920s and utilized by both Germany in World War II and South Africa during its. For the assumed Base Case minimum returns on investment are judged to be likely when crude oil is priced between 1400 to 1600 per barrel and more attractive returns are judged to be likely when crude oil is priced at a.

Source: globalchange.mit.edu

Source: globalchange.mit.edu

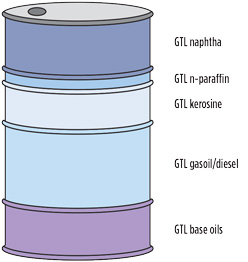

Gas-to-liquid GtL technologies first convert natural gas into syngas then it into liquids such as methanol FischerTropsch fuels or dimethyl ether. The resulting products include diesel and gasoline as well as waxes. 2004 152 406-481 p436. The first method called the base case utilizes oxygen as fuel for combustion of natural gas while the proposed case uses steamCO2 instead of Oxygen. GTL can also make waxes.

The aim is to ascertain a more economically viable GTL configuration for an optimal GTL process. Gas-to-liquids technologies typically use the Fischer-Tropsch Process to convert natural gas to petroleum products. Mahdifasihilutfi dmitriibogdanovlutfi christianbreyerlutfi Abstract. While manufacturing economics are reviewed the. Gas-to-Liquids GTL technologies can offer adequate monetization of small associated gas volumes in scattered locations in the Niger Delta.

Source: oil-gasportal.com

Source: oil-gasportal.com

The aim is to ascertain a more economically viable GTL configuration for an optimal GTL process. Gas to liquids GTL technologies natural gas liquids NGL extraction technologies 1. 1 2005 The Economics of Gas to Liquids Compared to Liquefied Natural Gas by Michael J. These associated gases were flared before because they were not needed and as such were. Gas-to-liquid GtL technologies first convert natural gas into syngas then it into liquids such as methanol FischerTropsch fuels or dimethyl ether.

Source: gasprocessingnews.com

Source: gasprocessingnews.com

Process Economics Program Report 247B SMALL SCALE GAS-TO-LIQUIDS TECHNOLOGY December 2011 Fischer-Tropsch synthesis generally involves the synthesis of alkane waxes of varying chain lengths and oxygenates from synthesis gas syngas which consists primarily of a mixture of carbon monoxide and hydrogen. These factors combine to result in lower capital and operating costs. Methane is the second highest contributor to the greenhouse effect. Economics of global gas-to-liquids GtL fuels trading based on hybrid PV-Wind power plants Mahdi Fasihi ymahdifasihilutfi 4 Motivation íFossil fuels increasing demand diminishing resources emissions íRE available but energy system transformation is challenging fluctuating RE and energy storage 100 electrification impossible for mobility sector. The aim is to ascertain a more economically viable GTL configuration for an optimal GTL process.

Source: oil-gasportal.com

Source: oil-gasportal.com

The most common technique used at GTL facilities is Fischer-Tropsch F-T synthesis. Economics of global gas-to-liquids GtL fuels trading based on hybrid PV-Wind power plants Mahdi Fasihi Dmitrii Bogdanov and Christian Breyer Lappeenranta University of Technology Lappeenranta Finland E-mails. Flaring-associated natural gas from remote oil reservoirs is currently the only economical alternative. This work evaluates the economics of GTL plant using two synthesis gas methods. The economics of GTL are primarily a function of the feedstock gas price the capital and operating costs and the oil price Hay 2009.

Economics of global gas-to-liquids GtL fuels trading based on hybrid PV-Wind power plants Mahdi Fasihi Dmitrii Bogdanov and Christian Breyer Lappeenranta University of Technology Lappeenranta Finland E-mails. Low feedstock gas prices coupled with high crude oil prices would ensure the economic viability of GTL. We will therefore use the more specific FTGTL abbreviation in place of GTL in order to focus on the process of synthesising liquid hydrocarbons from natural gas through the Fischer-Tropsch Synthesis FT-synthesis. Gas-to-liquids technologies typically use the Fischer-Tropsch Process to convert natural gas to petroleum products. Liquid phase including in the widest interpretation LNG Natural Gas Liquids NGLs and dimethyl ether DME.

Source: gasprocessingnews.com

Source: gasprocessingnews.com

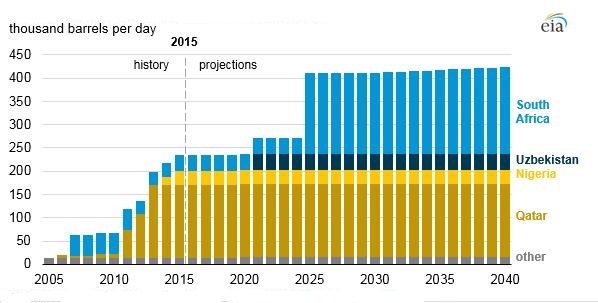

The most common technique used at GTL facilities is Fischer-Tropsch F-T synthesis. Early on natural gas was identified as a better feedstock for commercial FT operations than coal because of how effi-ciently it converted to synthesis gas how easy it was to handle and how few im - purities it had. These factors combine to result in lower capital and operating costs. We will therefore use the more specific FTGTL abbreviation in place of GTL in order to focus on the process of synthesising liquid hydrocarbons from natural gas through the Fischer-Tropsch Synthesis FT-synthesis. EIA estimates global production from GTL facilities currently averages about 230000 barrels per day bd or about 02 of global liquids production.

Source: gasprocessingnews.com

Source: gasprocessingnews.com

The first method called the base case utilizes oxygen as fuel for combustion of natural gas while the proposed case uses steamCO2 instead of Oxygen. Gas-to-liquids GTL has emerged as a commercially-viable industry over the past thirty years offering market diversification to remote natural gas resource holders. Gas-to-liquids technologies typically use the Fischer-Tropsch Process to convert natural gas to petroleum products. The case for gas-to-liquids Economic justification There is an economic incentive for gas-to-liquids conversion when there is a meaningful price difference between natural gas and crude oil. For the assumed Base Case minimum returns on investment are judged to be likely when crude oil is priced between 1400 to 1600 per barrel and more attractive returns are judged to be likely when crude oil is priced at a.

The economics of GTL are primarily a function of the feedstock gas price the capital and operating costs and the oil price Hay 2009. Natural gas to liquids technology appears to have reached the threshold of economic attractiveness when gas is priced at about 050 per Mscf. This article covers a micro-cap stock. Mahdifasihilutfi dmitriibogdanovlutfi christianbreyerlutfi Abstract. NGLs enter the processing plant as gas in the inlet stream and then are extracted and converted exiting the plant as liquids.

Source: frontier-economics.com

Source: frontier-economics.com

This is best illustrated with an example. Click to enlargeEditors Note. GTL can also make waxes. This paper examines the economics of Fischer-Tropsch gas to liquids manufacture using recent literature articles to develop process capital costs operating expenses liquid product value parameters and other economic factors to paint a general picture of the technologys current economic status. Methane is the second highest contributor to the greenhouse effect.

Source: oil-gasportal.com

Source: oil-gasportal.com

Early on natural gas was identified as a better feedstock for commercial FT operations than coal because of how effi-ciently it converted to synthesis gas how easy it was to handle and how few im - purities it had. Methane is the second highest contributor to the greenhouse effect. Early on natural gas was identified as a better feedstock for commercial FT operations than coal because of how effi-ciently it converted to synthesis gas how easy it was to handle and how few im - purities it had. The GTL process utilizes the Fischer Tropsch process to convert gas to liquid fuels a technology dating back to the 1920s and utilized by both Germany in World War II and South Africa during its. EIA estimates global production from GTL facilities currently averages about 230000 barrels per day bd or about 02 of global liquids production.

Source: oil-gasportal.com

Source: oil-gasportal.com

1 2005 The Economics of Gas to Liquids Compared to Liquefied Natural Gas by Michael J. Economics of global gas-to-liquids GtL fuels trading based on hybrid PV-Wind power plants Mahdi Fasihi Dmitrii Bogdanov and Christian Breyer Lappeenranta University of Technology Lappeenranta Finland E-mails. This paper examines the economics of Fischer-Tropsch gas to liquids manufacture using recent literature articles to develop process capital costs operating expenses liquid product value parameters and other economic factors to paint a general picture of the technologys current economic status. The case for gas-to-liquids Economic justification There is an economic incentive for gas-to-liquids conversion when there is a meaningful price difference between natural gas and crude oil. Flaring-associated natural gas from remote oil reservoirs is currently the only economical alternative.

Source: aogr.com

Source: aogr.com

Gas-to-liquids technologies typically use the Fischer-Tropsch Process to convert natural gas to petroleum products. Natural Gas using GTL zNeed for economic utilization of associated gas zDesire to monetize significant reserves of non-associated and particularly stranded natural gas 80 of the 5000 TCF proven NG reserves are stranded zReduction in cost of transport of NG from producing to consuming regions same principle as with LNG zEnvironmental concerns. Its global warming potential is 37 times that of CO2. Process Economics Program Report 247B SMALL SCALE GAS-TO-LIQUIDS TECHNOLOGY December 2011 Fischer-Tropsch synthesis generally involves the synthesis of alkane waxes of varying chain lengths and oxygenates from synthesis gas syngas which consists primarily of a mixture of carbon monoxide and hydrogen. Methane is the second highest contributor to the greenhouse effect.

Source: pnas.org

Source: pnas.org

Economides Professor University of Houston Editors note. The most common technique used at GTL facilities is Fischer-Tropsch F-T synthesis. These associated gases were flared before because they were not needed and as such were. Flaring-associated natural gas from remote oil reservoirs is currently the only economical alternative. Gas-to-liquid GtL technologies first convert natural gas into syngas then it into liquids such as methanol FischerTropsch fuels or dimethyl ether.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title gas to liquids economics by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.